More than Information Systems and Technology

Executive Summary

As a senior decision maker do you sometime ask yourself, “Why does it take so long to get our new ideas implemented?”

Modern manufacturing companies have success implementing modern models of management, the most widely adopted being quality systems and improvements, Theory of Constraints and various forms of Lean Manufacturing and Six Sigma. These methods are most successful when a culture of continuous improvement develops across the enterprise. This culture inspires ‘trying new ideas’ regardless of where they come from.

However, many companies’ Enterprise Resource Planning (ERP) and financial reporting systems fail to integrate these new ideas and innovations. Managers, out of desperation to have the right tools and reports, start building side systems to get what they need. Often these homegrown systems, such as elaborate Excel spreadsheets, are what IT professionals label ‘shadow IT’, meaning they are unsupported by the company’s IT. Or worse, the systems aren’t designed well and end up giving out erroneous or useless reports.

Finally, another poor outcome ignoring innovations and quality improvements are the related production costs get dumped into overhead. This results in production margins being inaccurate and financial results that are at best misaligned or at worst leading to management mistakes.

The Dunham Group offers a proven method to optimize legacy ERP and other Information Systems, integrated with people, processes and continuous improvement. This method starts with understanding people, processes and continuous improvement and new approach to planning and management supported by information technology.

A Story of Best Laid Plans – Case Study

The Plan

Many years ago, a manufacturing company hired us to build a new modern manufacturing information system (ERP). The company was growing and having difficulty financing its new sales demand. The primary return on investment driver was an expected boost in cash by reducing the cycle time of purchase order to payment (‘order to cash’). The project team included all the primary managers, accounting, procurement, production, quality, and sales.

The Missing Piece

The new ERP system was implemented and went live successfully. However, over time the expected cycle time reductions did not happen. This situation created tense confrontations, trying to figure out why (root cause). After several weeks of meetings, it was finally discovered, by accident, that the information bottleneck was one process, material demand forecasting was missed during development. While visibility of new orders, production status, inventory levels, and shipments had been automated, the purchasing department was still relying on their pre-existing system, an Excel spreadsheet.

An All-Too-Common Outcome

Understanding and automating this process worked eventually. Cycle times shrank dramatically, and the return on investment (ROI) occurred. However, the project cost and timeline ballooned, and the ROI was delayed – slowing the company’s growth.

How to Make Sure Your Company Beats the Odds

It is common knowledge that the odds of a successful ERP implementation are poor, ranging from a high of 50% to a low of 10%! The case study above was no exception. It occurred early in our careers. With years of experience and hundreds of ERP projects completed, we learned how to ensure ERP projects are successful.

Misalignment of physical processes, people, information and reporting creates risks, obstacles and plummets effectiveness, and increases costs. Alignment of these factors creates success, reduces costs, and escalates effectiveness.

Continuous Improvement – ERP is Often the Bottleneck

Not being aware of bottlenecks created by automation can, ironically, reduce or eliminate your ROI. Once you define and understand, people, processes and information needs, ERP systems can be optimized and bottlenecks removed, especially with new tools and technologies on the market. We can help ensure you have the systems to successfully move forward with continuous improvement.

Our Proven Method of Success

First, Do No Harm

Optimize your current ERP system. To start with we do not recommend investing in a new ERP system or even upgrading. First, thoroughly define and understand your business processes and existing systems, ensuring a critical element is not overlooked.

Phase One Approach

First, define and understand processes, people and information needs. The best methodology is process, people and information value stream mapping and costing to ensure we mutually define, understand business. Only then can we set the scope, priorities and goals and objectives of the project.

Task 1 – Full Life Cycle Assessment

- From Sales and operations planning, through operations, manufacturing, quality functions, and delivery the value stream is assessed. The assessment includes information flow, reports, IT systems and applications, ERP and communication with equipment, people and processes.

- The physical activities as well as electronic activities (phone, computer and technology) will be assessed. Observations and interviews are used to gather data and input. Activities and information flow are documented. Firsthand observation, interviews and individual Team Member/employee input are incorporated to make assessment a team building, as well as a process improvement, activity. Assessment may include electronic modeling (i.e. Promodel or other tool).

Task 2 – Discover Key Performance Indicators, Metrics, and Reporting Requirements

- Issues, constraints/ bottlenecks and opportunities are documented, along with root cause and potential solutions. The assessment and root cause analysis are used to plan for effective corrections and improvements. The analysis is used to prioritize improvements, based on cost, impact to the organization and ease of implementation. From these agreements will be reached with the management team on KPI’s, metrics, and reporting requirements.

Phase Two Approach

First, define and understand processes, people and information needs. The best methodology is process, people and information value stream mapping and costing to ensure we mutually define, understand business. Only then can we set the scope, priorities and goals and objectives of the project.

Task 1 – Project Plan

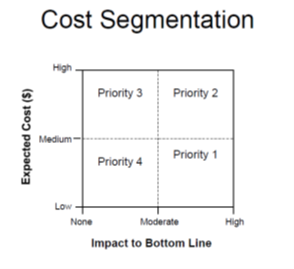

- A project plan to implement improvements is created with the business leadership team. The project plan is based on the “Quick Wins” identified by the leadership team and evolves and iterates to build momentum. To assist in prioritizing quick wins, we will utilize this cost segmentation measurement tool.

Task 2 – Evaluate Current ERP

- With the metrics, Key Performance Indicators ( KPIs), and priorities in hand, we review and analyze your current ERP systems. The primary objective is to ensure that people have access to the information they need, when they need it, in form they can understand.

Phase Three Approach

Ensure ERP Supports Continuous Improvement

We will work with you to ensure the ERP systems support and implement continuous improvement. This is often where either the initial ERP implementation or current IT Team struggle. Change management processes will be planned for future iterations, growth and success.

Conclusion

In many cases profound improvements in operations and financial results can occur quickly with very high ROI. Most of our projects return the entire investment in under 12 months, many even faster.

The unique process of a working implementation team to both discover, understand and document a value steam and then connect it to ERP outcomes can ensure your ERP system finally deliver the results you expect!

Enterprise resource planning (ERP) is a software system that helps organizations streamline their core business processes—including finance, HR, manufacturing, supply chain, sales, and procurement—with a unified view of activity and provides a single source of truth.

For More information, contact Ethan Dunham. Ethan.Dunham@dunhamgrouppdx.com